How Changes in Aircraft Design and Components Reduce Fuel Consumption?

Aircraft fuel efficiency has become increasingly important in recent decades due to rising fuel costs and environmental concerns. Aircraft manufacturers are using innovative new technologies and design principles to reduce fuel burn and emissions. Even small reductions in fuel consumption can result in huge cost savings for airlines over the lifetime of an aircraft. This article explores the various ways that advances in aircraft design and components are improving fuel economy.

Aerodynamic Improvements

A major focus area for improving fuel efficiency is enhancing the aerodynamics of the aircraft. Smoother surfaces, optimized wing design, and addition of winglets allow air to flow over the aircraft more efficiently, reducing drag.

Smoother Aircraft Surfaces

Earlier generation aircraft had many seams, edges and joints that caused drag-inducing turbulence in the airflow. Modern aircraft now use advanced manufacturing techniques to eliminate unnecessary gaps and create perfectly smooth surfaces. Composite materials like carbon fiber are molded into seamless structures for wings, tails and fuselages. The improved aerodynamics from these smoother surfaces reduces fuel burn.

Advanced Wing Design

Swept wings were a transformative innovation in last century, greatly reducing drag at higher speeds compared to straight wings. Today’s wings have optimized sweep angles for current flight requirements. Wings are designed for optimal lift-to-drag ratios at typical cruise conditions. Sophisticated computer modeling allows fine tuning of wing shape to minimize drag.

Wings are getting thinner too. In the quest to reduce weight, manufacturers use lighter, stronger composite materials in wings. Thinner wings disturb the airflow less, cutting down on drag-inducing vortices.

Wingtip devices like winglets, raked wingtips and feathered wingtips reduce drag and increase fuel efficiency by stopping wasteful wingtip vortices. Winglets can improve fuel consumption by up to 5%.

Laminar Flow Control

Aircraft wings are usually designed to have laminar flow on the forward section and turbulent flow towards the rear. Turbulent airflow creates more skin friction drag. Advanced designs aim to maintain laminar flow for as long as possible.

Special wingskin materials, small perforated tubes sucking air through the surface, and minimal surface gaps all help delay transition to turbulence. Laminar flow control can reduce overall aircraft drag by up to 15%.

Lighter and Stronger Materials

Replacing heavy materials with lighter alternatives reduces aircraft weight and fuel burn:

- Composites like carbon fiber and fiberglass replace sheets of metal in wings, tails and fuselages. They are up to 20% lighter.

- Titanium and advanced aluminum alloys substitute heavier steels in bulkheads, landing gear and engines. They weigh 40% less.

- Plastics and carbon fiber replace heavy glass and metals in cockpit canopies and passenger windows.

Lighter interiors also trim weight. Carbon fiber seats are 50% lighter than traditional metal framed seats. Even onboard carts and galleys use lightweight materials.

Despite being lighter, modern materials like composites and advanced aluminum alloys also have greater strength, allowing further reductions in component weight.

Improved Aerodynamics of Aircraft Components

Design tweaks on various aircraft components also incrementally improve efficiency:

- Tails with reduced span and area cut down on drag while still providing required stability.

- Slimmer turbine engine cowlings reduce frontal area and drag. Riblets on cowls align airflow.

- Landing gear doors and supporting struts are contoured for minimum drag.

- Small vortex generators on aircraft surfaces reduce airflow separation.

- Flap track fairings streamline the cavity behind deployed flaps.

More Efficient Aircraft Engines

Aircraft engines burn enormous quantities of fuel. Even small percentage improvements in engine efficiency cumulatively add up to impressive savings:

- High bypass ratio engines waste less power and burn up to 15-20% less fuel than early turbofans.

- New lightweight materials like composites and titanium alloys reduce engine weight.

- Computerized engine control systems continuously fine tune fuel burn for optimal efficiency.

- Improved turbofan blade shape and materials maximize thrust while minimizing drag.

- Cooling and sealing technologies reduce internal engine leaks that sap power.

- Clever heat recovery systems reuse energy dissipated as heat.

- Ceramic coatings like thermal barrier coatings insulate hot engine parts, improving combustion efficiency.

Reduced Energy Requirements

Airplanes need power on board not just for propulsion, but also to run aircraft systems. Recent design changes have reduced electricity and pneumatic power demands:

- Digital glass cockpit displays replace older analog electro-mechanical instruments.

- LED cabin lighting cuts power draw. Smart zoning activates lights only in occupied areas.

- Electric taxiing systems allow taxiing without engine thrust.

- Enhanced electric motors power compressors and actuators more efficiently.

- Heat exchangers scavenge waste heat to run water heaters and galleys.

- Lighter seats and carts need less propulsive force to move.

Even small reductions in ancillary power needs cumulatively reduce engine loading and fuel consumption.

Optimal Cruise Speeds and Altitudes

Airlines optimize flight plans to operate at the most fuel efficient cruise speeds and altitudes for each trip. This maximizes fuel savings within safety limits:

- Long-range cruising altitude is just below the tropopause where thin air causes minimal drag.

- Optimal cruising speeds maximize lift-to-drag ratios for each aircraft type and loading. Slower speeds burn less fuel.

- Steeper climb gradients reach optimal altitudes faster, saving fuel.

- Cruise speed reductions as low as 1-2% significantly improve efficiency over long flights.

- Smoother descents with low engine power stretch glide ranges.

Weight Reduction Efforts

Every pound of weight reduced on an aircraft cuts annual fuel consumption significantly over its service life. Airlines and manufacturers are working to minimize weight through:

- Lighter seats, galleys, carts, lavs and other interiors.

- Reduced water and beverage carriage with on-demand systems.

- Lighter duty catering equipment.

- Electronic flight bags replace heavy paper charts and manuals.

- Limited repainting. Fresh paint adds hundreds of pounds.

- Tankering optimization. Carrying only required fuel lowers weight.

- Removal of unneeded galley inserts and other discarded equipment.

- Lightweight composite cargo containers and pallets.

Ongoing Innovation

Aircraft fuel efficiency has already improved tremendously over past generations. However there is scope for more gains through ongoing innovations like:

- New engine cycles like geared turbofans, pressure gain combustors.

- Hybrid electric and fully electric aircraft designs.

- Laminar flow wing designs using active flow control.

- Structural power harvesting to reduce parasitic drag.

- Continued weight reductions via nanomaterials and 3D printing.

- Improved flight path optimization and dynamic engine tuning.

Conclusion

Aircraft fuel consumption is a major cost factor for airlines and an environmental concern globally. Manufacturers invest billions into developing technologies that improve efficiency even slightly. Airlines also optimize operations and loading to burn less fuel. The steady stream of improvements from revised aerodynamics, lightweight materials, more efficient engines and reduced onboard power needs have together delivered major reductions in aviation fuel burn. Further advances promise continued enhancement in the efficiency of air transport.

Frequently Asked Questions

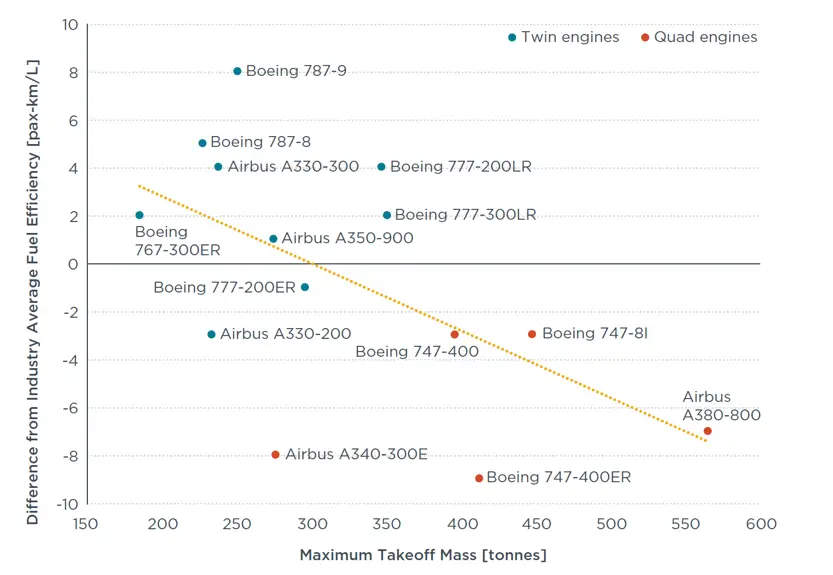

How much fuel efficiency have new aircraft gained versus older models?

Aircraft efficiency gains are typically 1-2% per year. Over decades this compounds to massive savings. The Boeing 787 burns 20% less fuel than the Boeing 767 it replaces. The Airbus A320neo burns 15-20% less fuel than the original A320 family.

What are winglets and how do they reduce fuel consumption?

Winglets are vertical wing extensions at the wing tips. They reduce drag and improve efficiency by stopping the sideways air leakage from the high pressure areas below the wing around the wingtips into the low pressure area above. Preventing this vortex leakage makes the aircraft more aerodynamic.

How does reducing aircraft weight lead to lower fuel burn?

A lighter airplane needs less thrust and fuel to fly. For most aircraft, each pound of weight reduction decreases fuel consumption by over a gallon per year. New composites and alloys have enabled planes like the A350 and 787 to be much lighter than older generations.

Which engine improvements give the best efficiency gains?

High bypass ratio turbofans waste less power on jet exhaust and provide most of the thrust from the fan bypass air. They burn 15-20% less than early turbofans. New materials like composites and variable geometry intakes also improve performance.

How do smoother aircraft surfaces reduce drag?

Early aircraft had many seams, gaps and joints that caused turbulence in the airflow over wings and other surfaces. Modern advanced composites and manufacturing methods create perfectly smooth surfaces without seams, which reduce drag significantly.