Wind Turbine Inspection Drone

Looking for a more efficient, accurate way to inspect wind turbines? Look no further than the wind turbine inspection drone – an efficient method that uses drones to gather detailed data and imagery of the wind turbine blades and structure.

With high-resolution cameras and other specialized sensors, these drones can quickly and accurately assess the condition of wind turbines and identify any potential damage or defects. They also offer improved safety compared to traditional manual inspections, as they can be flown directly to hard-to-reach parts of turbines without requiring workers to climb potentially dangerous areas.

And as drone technology continues to improve and become more widely adopted, it is likely that we will see even greater use of wind turbine inspection drones in the wind power industry.

So if you’re looking for an efficient, reliable way to inspect wind turbines, you should consider the use of a wind turbine inspection drone.

How do Drones Inspect Wind Turbines?

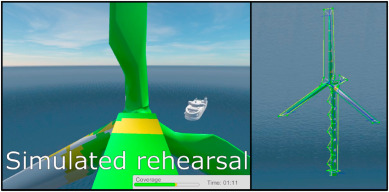

In order to inspect wind turbines, a drone is first equipped with necessary equipment such as high-resolution cameras, ground radar, or other sensors as per the inspection requirement, which allows it to monitor the turbine blades and structure.

The drone then flies over the wind turbine and captures detailed images as well as a range of other data from respective sensors. These data are then analyzed to identify any damage or defects, and any areas that need further inspection are marked.

Overall, using drones to inspect wind turbine blades is a cost-effective, accurate, and efficient way to maintain the safety and performance of these important components.

And as drone technology continues to evolve and improve, we can expect this method of inspection to become even more widespread in the wind power industry.

Benefits of Using Drones for Wind Turbine Inspection

Drones Provide a Broader Range of Data with High-resolution Imagery

Drones are capable of carrying digital or thermal cameras which allows them to gather a large amount of detailed, high-quality imagery and other relevant data.

This data is crucial for assessing the performance and safety of wind turbines, as it allows engineers and maintenance workers to identify potential issues before they become more serious problems.

Faster Inspection

Drones enable faster, more efficient inspections of wind turbine blades and structures. Drones can be flown directly up to the blades, and equipped with specialized sensors, they are able to capture data about any damage or wear on the blades.

Improved Safety

In addition to being faster and more efficient, using drones for this type of work is also safer than having a worker climb up the towers to inspect the blades.

This reduces the risk of accidents, which helps to keep workers safe and also minimizes downtime caused by accidents.

Reduce Cost

Traditionally, wind turbine inspections have been carried out manually by teams of engineers, who climbed up the wind turbine structure to access hard-to-reach parts of the turbine to assess structural integrity and collect data.

The traditional method of wind turbine inspection is an expensive and time-consuming process when it has to be carried out for multiple wind turbines in a wind farm.

Drone technology has the potential to change this situation, as drone-based inspections can be conducted quickly and remotely, reducing costs by up to 70%, as per a research study.

In addition, drones are able to access areas that are typically hard to reach, such as the top of turbines. This makes drone-based wind turbine inspections more thorough than traditional manual inspections, as they can identify potential problems that might not have been immediately noticeable.

Overall, drone-based wind turbine inspections are an innovative, cost-effective technique that can help reduce inspection times, and costs while improving safety during wind turbine inspection.

Using automation and drones, you can potentially inspect 20 turbines every day. And a faster inspection process and lesser human intervention means that you ...

The cost of wind turbine blade maintenance is up to AUD $5,000 per tower. With 400,000 onshore wind turbines globally, regular maintenance adds up quickly. ...

Drone data is known to be clear, precise, and of high-resolution. UAVs furnished with high-quality cameras can precisely seize aerial photographs and videos of ...

Looking for a more efficient, accurate way to inspect wind turbines? Look no further than the wind turbine inspection drone – an efficient method that uses ...

AI-based autonomous drones can complete visual inspections for the entire turbine in as little as 15 minutes, which is 10 times more efficient than traditional ...

“Choosing a drone for wind-turbine blade inspections is the safer choice,” says Ben Marchionna, Head of Global Operations at SkySpecs, a U.S.-based robotics ...

Companies have adopted drone programs to inspect assets because drones get the job done more efficiently while keeping people safe from the potential risks of ...

Drones can be used to offer a full site evaluation or to inspect a single wind turbine. These drones equipped with high-performance cameras can examine a wind ...

Drone inspections for solar facilities, Measure said, are 95% more efficient and identify defects, tracker misalignment, shading, tower and substation ...

Consumer drones are a fraction of the cost of commercial ones and may entice some wind-farm owners. Unfortunately, consumer UAVs are unsafe to fly at wind ...

Rope-access inspection is used as a baseline and accounts for 0.7% of the wind farm operational expenditure. Replacing rope-access inspection with drones ...

Traditionally, wind turbine inspection has been a slow process that is inherently dangerous. Often, wind turbines would need to be inspected manually, both ...

This technology makes it possible to detect structural incidents in wind turbine blades and serve as a guide during maintenance, saving considerable costs and ...

“It has been very exciting how this industry has grown in the past three or four years,” said Harjeet Johal, CEO of drone services firm Aerodyne Measure in ...